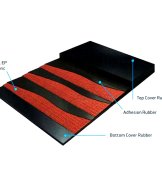

CANVAS FABRIC is a kind of belting fabric (also called conveyor belt fabric).Belt fabric is widely used in producing rubber belt and rubber patch,It is a also a good material to make tent,luggage,bags and outdoor advertising curtain cloth.It can also can be used as diaphragm fabrics.We can produce EE fabric,EP fabric ,NN fabric and PP fabric

1. EP Raw material structure

The warp of EP fabric is in form of polyester industrial filament,and the weft is in form of nylon6.6(chinlon6.6)industrial filament and RFL dipping glue.

2. Model

EP-80,EP-100,EP-125,EP-150,EP-160,EP-200,EP-250,EP-300,EP-350,EP-400,EP-450,EP-500

3.Product features

High intensity

Good heat resistance

Long servic life

| Specification item | Unit | EP-250 | EP-300 | EP-400 | EP-500 | ||||

| Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | ||

| Frame | Dtex | 1100*4 | 1870*2 | 1100*4 | 1870*2 | 1670*3 | 1870*2 | 1670*4 | 1400*3 |

| Ensity | 根/10cm | 120±2 | 38±2 | 146±2 | 38±2 | 150±2 | 38±2 | 125±2 | 38±2 |

| ≧ Average breaking strenght | N/mm | 330 | 105 | 350 | 105 | 400 | 105 | 465 | 105 |

| ≧ Mnimum breaking strength | 290 | 95 | 320 | 95 | 370 | 95 | 425 | 95 | |

| ≦ Fixed extension constant load elongation | % | 1.5 | 1.5 | 1.5 | 2.5 | ||||

| ≦ Breaking elongation | % | ≧15 | ≦45 | ≧15 | ≦45 | ≧15 | ≦45 | ≧15 | ≦45 |

| ≦ Drying shrinkage (150℃*30min) | % | 5.0 | 0.5 | 5.0 | 0.5 | 6.0 | 0.5 | 6.0 | 5.5 |

| ≦ Dry heat shrinkable irregularity | % | 10 | 10 | 10 | 10 | ||||

| ≧ Ddhesive strength | N/mm | 7.8 | 7.8 | 7.8 | 7.8 | ||||

| Thickness | mm | 1.07±0.10 | 1.20±0.10 | 1.26±0.10 | 1.40±0.10 | ||||

Low elongation

Good troughability

Strong adhesion force

4.Applications

It can be used for conveyor belt under condition of long distance , large load , high speed and strong chemical corrosion,etc .

5.Common index

Can be customized according client’s technical specification

| Specification item | Unit | EP-80 | EP-100 | EP-125 | EP-150 | EP-200 | |||||

| Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | ||

| Frame | Dtex | 1100*1 | 930*1 | 1100*1 | 930*1 | 1647*1 | 1400*1 | 1100*2 | 1870*1 | 1100*2 | 1400*2 |

| Ensity | 根/10cm | 155±2 | 76±2 | 194±2 | 86±2 | 170±2 | 72±2 | 166±2 | 56±2 | 186±2 | 44±2 |

| ≧ Average breaking strenght | N/mm | 100 | 50 | 137 | 55 | 165 | 70 | 206 | 75 | 246 | 85 |

| ≧ Mnimum breaking strength | 95 | 45 | 118 | 50 | 145 | 60 | 176 | 68 | 220 | 75 | |

| ≦ Fixed extension constant load elongation | % | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |||||

| ≦ Breaking elongation | % | ≧14 | ≧14 | ≦45 | ≧14 | ≦45 | ≧14 | ≦45 | ≦45 | ||

| ≦ Drying shrinkage (150℃*30min) | % | 5.0 | 0.5 | 5.0 | 0.5 | 5.0 | 0.5 | 5.0 | 0.5 | 5.0 | 0.5 |

| ≦ Dry heat shrinkable irregularity | % | 10 | 10 | 10 | 10 | 10 | |||||

| ≧ Ddhesive strength | N/mm | 7.8 | 7.8 | 7.8 | 7.8 | 7.8 | |||||

| Thickness | mm | 0.55±0.05 | 0.55±0.05 | 0.60±0.05 | 0.70±0.05 | 0.85±0.05 | |||||